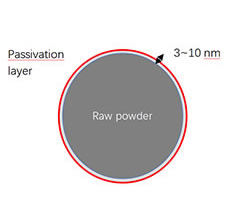

Nano level passivation layer coating technology: By using a 3-10nm insulating passivation layer, magnetic powder particles are uniformly coated, breaking through the limitations of traditional material eddy current losses and improving the stability of magnetic permeability in high-frequency environments.

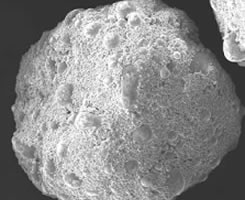

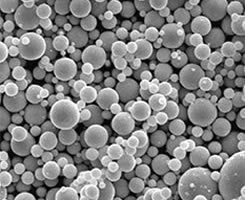

Multimodal magnetic powder system:Covering a full range of soft magnetic materials such as amorphous alloys, nanocrystals, iron silicon aluminum, etc., supporting customized formula development.

High temperature polymer bonding system: a self-developed polymer material system that meets the weather resistance requirements of automotive environments and has passed AEC-Q200 certification.

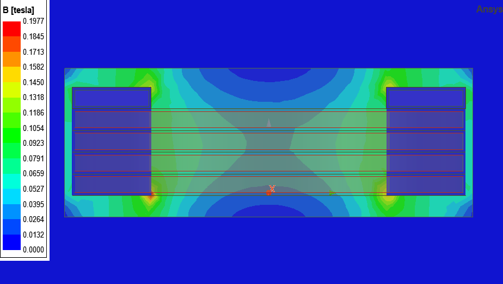

Full-Parametric Modeling Platform: Construct 3D electromagnetic-thermal-mechanical coupling models to accurately predict saturation current (Isat), temperature rise (ΔT), and component characteristics.

Structural Optimization Algorithm:Patented winding layout optimization reduces DCR under the same volume, assisting customers in overcoming spatial constraints.

Rapid Response Mechanism:By leveraging extensive accumulated cases and data models, swiftly provide feasible solutions that comply with customer specifications.

Full-Process Equipment Development: Independently designed core equipment including winding machines, powder molding machines, and testing & packaging systems, achieving ultra-high equipment utilization rate.

Flexible Production Line Architecture:Modular production lines support full-size inductor manufacturing, enabling rapid switching between industrial-grade, automotive-grade, and special high-temperature products.

Intelligent Inspection System:Integrated with AOI (Automated Optical Inspection), online LCR testing, and big data-driven SPC (Statistical Process Control), enabling real-time monitoring and control of key parameters.

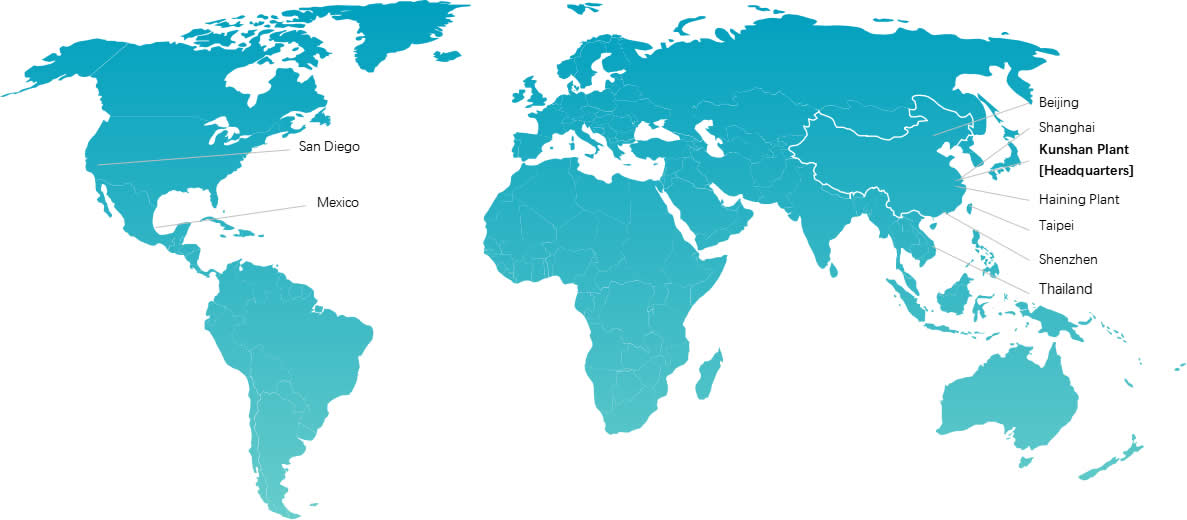

Kunshan Headquarters

Kunshan Headquarters Haining Factory

Haining Factory Thailand Fcatory

Thailand Fcatory Mexico Factory

Mexico Factory 0512-3686-9427

0512-3686-9427 sales@mazotech.com

sales@mazotech.com No. 600, Xinsheng Road, Huaqiao Town, Kunshan City, Jiangsu Province

No. 600, Xinsheng Road, Huaqiao Town, Kunshan City, Jiangsu Province